Backpack Fabric Guide: What is Oxford Fabric

This backpack fabric guide will take you on a deep dive into what Oxford cloth is, exploring the history and characteristics behind this popular material and how it has become a star player in modern backpack design. Join us as we uncover the wonders of Oxford cloth and understand its unique role in the world of backpack design.

I. What is Oxford Fabric?

A. Historical Background of Oxford Fabric

1. Origin and development of Oxford fabric

Oxford fabric traces its roots back to the 19th century in Scotland, where it was one of four fabrics named after the most prestigious universities of the time—Oxford, Cambridge, Yale, and Harvard. Originally designed for shirting, the fabric quickly became synonymous with classic, tailored clothing. Its unique basketweave pattern, which typically uses two fine yarns woven against a heavier one, gave it a distinctive appearance and feel that was highly valued in gentlemen’s attire.

2. Transition from clothing to backpack material

The durability and comfort of Oxford fabric made it a favorite for dress shirts, but these same qualities also caught the attention of manufacturers looking for robust materials suitable for everyday carry items. By the mid-20th century, as synthetic fibers and textile innovations emerged, Oxford fabric began to evolve from a staple of the wardrobe to a preferred material for various accessories, including backpacks. Its ability to withstand the rigors of daily use without compromising on style made it an excellent choice for bags and luggage.

B. Definition and Characteristics of Oxford Fabric

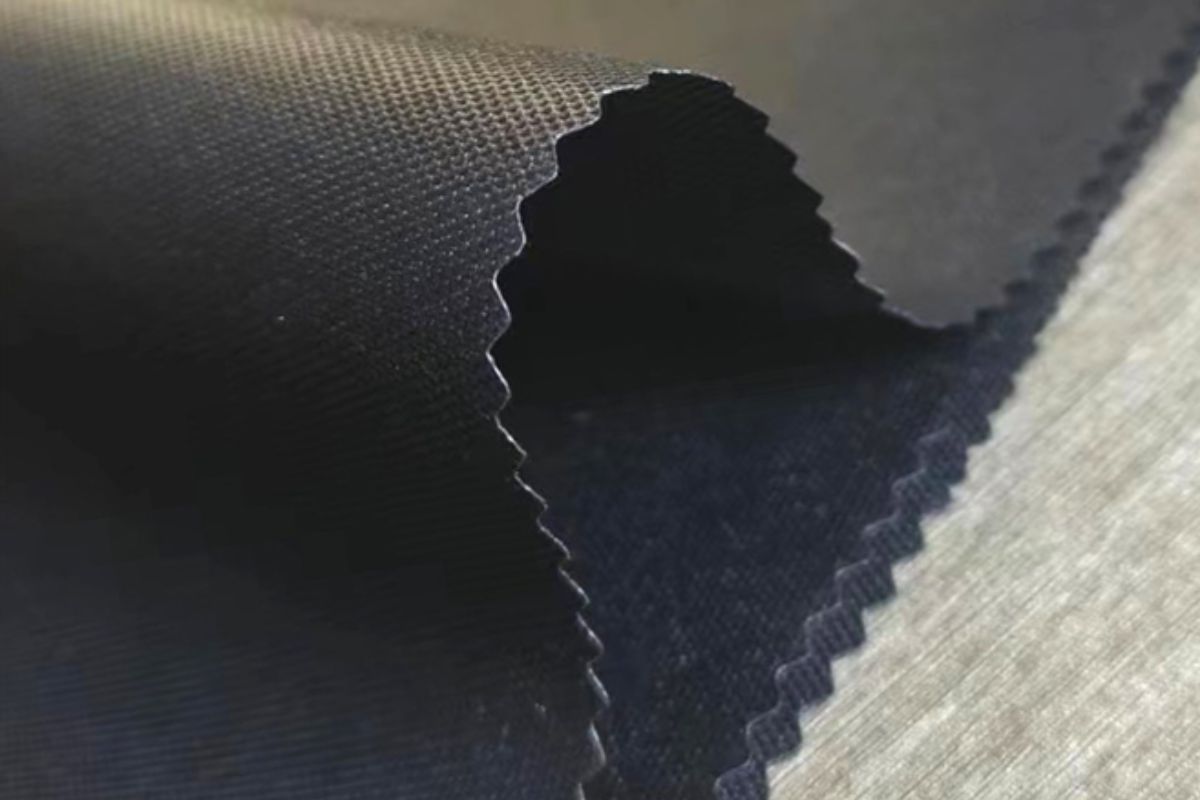

1. Description of its unique weave and texture

Oxford fabric is most commonly recognized by its basketweave structure, where multiple weft threads are crossed over an equal number of warp threads. This technique creates a subtle, checkerboard-like pattern that is tactile and visually appealing. The weave is not only attractive but also contributes to the fabric’s strength and breathability, making it suitable for a range of applications.

2. Key properties that differentiate it from other fabrics

What sets Oxford fabric apart from other materials are its key properties: it’s generally wrinkle-resistant, has a good level of natural luster, and maintains a crisp appearance. These characteristics are bolstered by the fabric’s inherent durability and capability to resist significant stress, which is why it has become a go-to material for items that require both form and function, such as backpacks.

C. Evolution of Oxford Fabric

1. Innovations in weaving techniques

Over time, weaving techniques for Oxford cloth have seen significant advancements. The introduction of blended fibers, such as polyester and cotton, has enhanced the fabric’s performance by increasing its resistance to wrinkles and reducing shrinkage. Additionally, new weaving technologies have allowed for tighter weaves and higher thread counts, which improve the fabric’s strength and finish.

2. Modern uses and adaptations in the textile industry

Today, Oxford fabric is utilized in a wide array of products beyond traditional shirting. Its application has expanded to include various types of apparel, home furnishings, and notably, backpacks and other carrying accessories. The textile industry continues to adapt Oxford cloth to meet modern demands, infusing the fabric with water-resistant coatings, UV protection, and even antimicrobial treatments to cater to a more health-conscious consumer. These adaptations ensure that Oxford fabric remains a versatile and reliable choice in a world where the lines between style, comfort, and practicality are increasingly blurred.

II. What is Oxford Fabric Made Of?

Oxford fabric, with its origins steeped in the tradition of classic British tailoring, is a type of woven dress material that has transcended its initial design to become a staple in various applications, most notably in the construction of durable and stylish backpacks. To understand what Oxford fabric is made of, we must delve into the materials and methods that contribute to its unique properties and versatile nature.

Traditionally, Oxford fabric was woven from pure cotton, prized for its softness, breathability, and natural feel. The hallmark of the fabric is its distinctive basketweave pattern, which is created by interlacing yarns in a manner that gives the material a slightly raised, textured appearance. In this classic weave, thicker yarns are crossed with finer ones, resulting in a durable yet comfortable fabric.

As textile technology has evolved, so too has the composition of Oxford fabric. Modern variations are often made from a blend of cotton and synthetic fibers such as polyester or rayon. These blended fabrics offer the benefits of both materials: the comfort and breathability of cotton combined with the durability, wrinkle resistance, and colorfastness of synthetic fibers. The introduction of synthetic elements has also allowed for the development of lighter-weight versions of Oxford fabric, which retain the original’s robust qualities while providing additional functionality and ease of care.

In some cases, especially when designed for outdoor gear and backpacks, Oxford fabric may be treated with various coatings or laminations to enhance its performance. For instance, a polyurethane (PU) coating can be applied to make the fabric water-resistant or even waterproof. Other treatments might include UV-blocking chemicals to prevent color fading or antimicrobial agents to resist odor and bacterial growth.

Additionally, the thread count of Oxford fabric can vary, with higher thread counts typically indicating a finer, denser weave that offers a smoother finish and a more luxurious feel. However, for backpacks and other items that require a higher degree of durability, a lower thread count with a heavier weave may be preferred for its strength and ability to hold shape.

In summary, Oxford fabric is made from either pure cotton or a blend of cotton and synthetic fibers, woven in a distinctive basketweave pattern that contributes to its durability and textured look. The choice of materials and the specific treatments applied to the fabric ultimately determine its suitability for various uses, from elegant dress shirts to rugged, all-weather backpacks. Its adaptability and enduring appeal lie in this unique combination of traditional craftsmanship and modern innovation.

III. Manufacturing Process of Oxford Fabric

Oxford fabric is known for its strength and versatility, which are attributed to its specific manufacturing process involving the careful selection of yarns and a series of mechanical and chemical treatments. The process not only gives this fabric its characteristic look and feels but also ensures its suitability for a variety of applications.

A. Weaving

At the heart of Oxford fabric production is the weaving process. It begins with the selection of quality cotton fibers or sometimes blended with synthetic materials to enhance properties. The yarns are then intricately woven using a basket weave pattern. This pattern typically involves one weft yarn crossing over two warp yarns, which adds to the fabric’s distinctive texture and durability.

B. Dyeing

Post-weaving, the fabric undergoes the dyeing process to achieve a wide spectrum of colors. This process is crucial for ensuring color fastness, where the dye molecules are thoroughly bonded with the fiber particles. The methods used must be precise to render colors that are both vibrant and resistant to fading from washing and sunlight.

C. Finishing

Finally, the fabric is finished with various treatments to improve its properties. These finishing processes can include softening, shrink resistance, and imparting a subtle sheen to the fabric surface. Each finishing technique is chosen based on the desired end use of the Oxford fabric, be it for apparel or other applications like bags and luggage.

IV. Different Types of Oxford Fabric and Weaves

With various types and blends, Oxford fabric accommodates a range of preferences from fine textures to more robust weaves.

A. Exploring the Varieties of Oxford Fabric

Plain Oxford – The classic style

Plain Oxford is known for its traditional basketweave structure. It typically features a one-over-one-under weave, which creates a durable yet comfortable fabric. This type of Oxford material presents a slight sheen with a smooth finish, robust enough for everyday wear.

Pinpoint Oxford – A finer, more detailed weave

As a variation with a tighter weave than plain Oxford, Pinpoint Oxford uses a finer yarn and a two-over-one-under thread pattern. The result is a fabric that’s still solid and somewhat coarse to the touch but with finer textures and a more elegant appearance suitable for dressier occasions.

Basketweave Oxford – A more open and breathable weave

This type of Oxford weave creates a more breathable fabric due to its looser basketweave structure. It often appears more casual because of its texture, which is achieved by crossing multiple warp threads over multiple weft threads.

Royal Oxford – Luxurious with a distinctive texture

Royal Oxford stands out with its elaborate weave, creating a well-defined and textured pattern. This fabric possesses a more pronounced shine and a dressier feel compared to the classic Oxford, making it ideal for more formal attire.

B. Composition and Thread Count

Understanding the importance of thread count

The thread count in Oxford fabrics is a significant factor in determining their quality. Higher thread counts typically denote a smoother and finer fabric, while lower counts lend to a more robust texture. The thread count directly affects both the aesthetic feel of the fabric and its strength.

Material blends and their impact on performance

Oxford fabrics may incorporate various blends of materials, including cotton, polyester, and other synthetic fibers. Cotton is commonly chosen for its comfort and breathability, while synthetics are added to enhance durability and wrinkle resistance. Fabric blends influence the fabric’s feel; for instance, cotton-polyester mixtures result in a material that’s easier to iron and maintain over time.

V. Advantages of Oxford Fabric for Backpacks

This section explores why oxford fabric is favored for its utility in crafting backpacks that endure rigorous daily use, maintain their aesthetic appeal and provide functional advantages to consumers.

A. Durability

Oxford fabric possesses durable, abrasion-resistant qualities, making it well-suited for backpacks that are frequently subjected to wear and tear. Its heavy weave contributes to a longer lifespan even under challenging conditions.

B. Versatility

With a range of weaves and weights, Oxford fabric can adapt to various types of backpack designs, from casual daypacks to specialized gear for outdoor use, providing comfort without sacrificing strength.

C. Lightweight

Despite its thicker weave, Oxford fabric remains relatively lightweight, ensuring that backpacks don’t add unnecessary weight, thereby reducing the strain on the user’s back and shoulders.

D. Breathability

Oxford fabric’s breathability is an inherent feature, helping to keep the contents of a backpack in a comfortable and ventilated condition, especially in warmer climates or during physical exertion.

E. Low Maintenance

Backpacks made from Oxford fabric are resistant to wrinkles and easy to clean, making them low maintenance and ideal for daily use without the need for frequent care.

F. Water-Resistance

One of the notable characteristics of Oxford fabric is its water resistance, which protects the backpack’s contents against moisture, making it suitable for travelers and commuters.

G. Resistance to Fading

The dyes used on Oxford fabric are resistant to fading, ensuring that backpacks retain their color and look newer for longer, even after extensive use and exposure to the elements.

H. Structural Stability

Because of its structural stability, Oxford fabric helps backpacks maintain their shape and protect the contents, enhancing the overall durability and usability of the bag.

I. Cost-Effectiveness

Oxford fabric offers a balance between performance and price, making it a cost-effective option for backpack manufacturers and consumers seeking quality at an affordable cost.

VI. Applications of Oxford Fabric

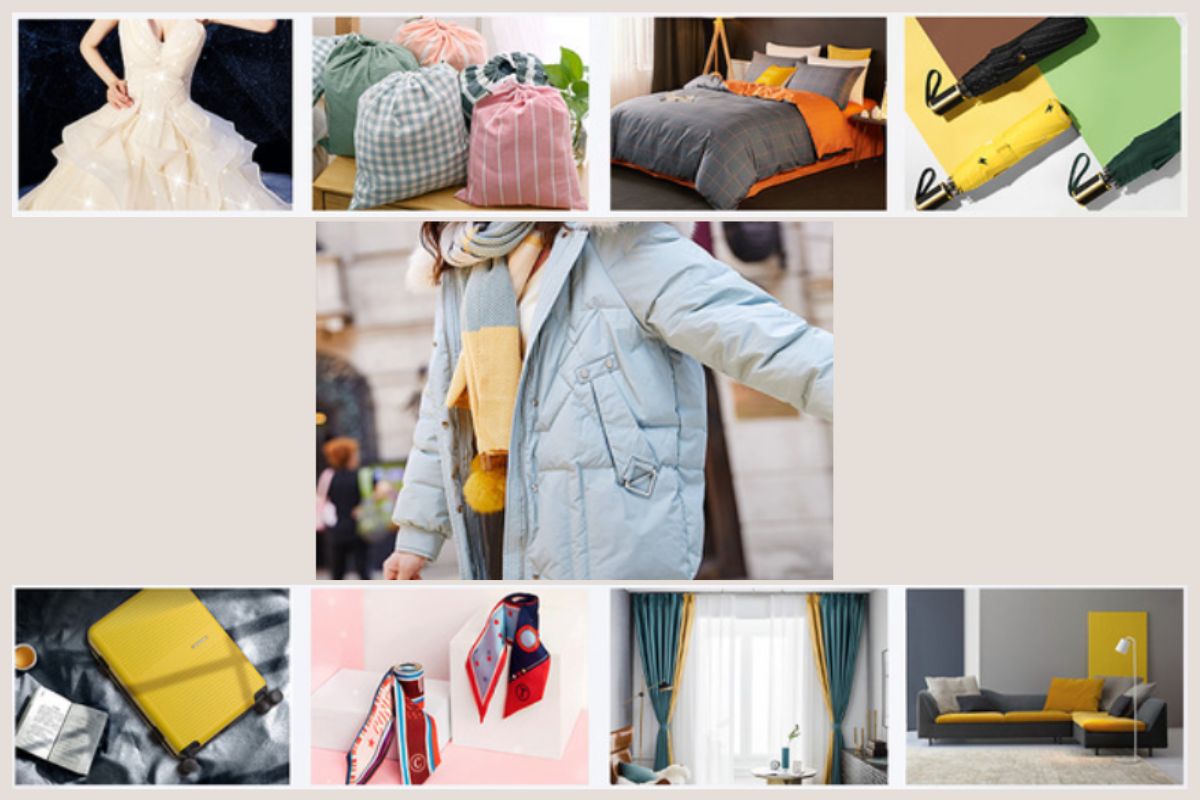

Originally linked with classic dress shirts, Oxford fabric’s applications have diversified across fashion, décor, and outdoor equipment.

A. Fashion and Clothing

Shirts: Dress and casual variations.

Bottoms: Includes pants and skirts.

Additional Wear: Utilized in dresses for added resilience.

B. Home and Decor

Cushion Covers: Durable and retains color well.

Upholstery: Applied to furniture for a classic look with longevity.

C. Outdoor and Gear

Tents: Chosen for its sturdiness and ability to endure diverse weather conditions.

Backpacks and Bags: Favored for its abrasion resistance and longevity.

Luggage: Utilized for its tear-resistant properties and robustness in travel conditions.

VII. Comparing Oxford Fabric to Other Backpack Materials

Oxford fabric, a popular choice, is weighed against other fabrics to determine its suitability for specific needs.

A. Oxford vs. Polyester

Oxford fabric, typically woven in a basketweave pattern, is renowned for its strength and durability, often outperforming polyester in resistance to abrasion. While both materials are synthetic, Oxford fabric tends to offer a more premium feel. Polyester, on the other hand, has high chemical resistance and is generally more cost-effective, making it a versatile option for various applications.

B. Oxford vs. Nylon

Nylon is a synthetic fiber known for its exceptional strength and elasticity. Compared to Oxford fabric, nylon is more lightweight and has superior water and chemical resistance, which contributes to its use in a wide range of outdoor gear. However, Oxford fabric often provides a sturdier structure for backpacks and may maintain its shape better over time.

C. Oxford vs. Canvas

Canvas, traditionally made from cotton or linen, offers robustness and high durability, akin to Oxford fabric. However, canvas tends to be heavier, providing a different balance of weight to strength ratio. Oxford fabric is favored for its lighter weight and often smoother texture, yet it maintains a comparable level of durability, making it a compelling choice for backpacks meant for daily use.

VIII. Choosing the Right Oxford Fabric Backpack

When selecting an Oxford fabric backpack, key considerations include the fabric’s weight, durability, utility aligned with the intended use. Each aspect contributes to the overall functionality and longevity of the backpack.

A. Assessing Weight and Denier for Durability

Oxford fabric is known for its strength, which is highly influenced by both weight and denier. Weight is the fabric’s heaviness per square meter and gives an indication of its bulk and comfort for carrying. Denier refers to the fabric’s thickness, with higher counts suggesting improved abrasion resistance. A durable Oxford fabric backpack should balance these elements to ensure it can withstand regular use without being uncomfortably heavy.

B. Matching Backpack to Intended Use

The choice of an Oxford fabric backpack should align with its intended purpose. For outdoor activities, look for options with a high denier count that offer enhanced durability. Day-to-day urban use might require a lighter backpack with moderate durability. Consider factors like:

Ingress protection for weather resistance.

Pocket configuration for organization.

Size that matches the load typically carried.

C. Additional Features to Consider

Aside from the core fabric properties, other features can enhance the functionality of the backpack:

Water resistance for protection against the elements.

Padded straps for ergonomics and comfort.

Breathability to prevent moisture build-up at the back.

IX. Care and Maintenance of Oxford Fabric Backpacks

Proper care extends the life and appearance of your Oxford cloth backpack. This section outlines cleaning, storage, and more for these durable backpacks.

A. Cleaning and Stain Removal Best Practices

To clean an Oxford fabric backpack, first shake out any loose debris. Use a soft brush to gently remove dirt from the surface. For stains, prepare a mixture of mild detergent and lukewarm water, and apply it gently with a soft cloth or sponge. Avoid using bleach, as this can damage the fabric’s color and integrity.

Spot Cleaning

Apply the cleaning solution directly to stains.

Blot with a damp cloth until the stain lifts.

Machine Washing

Only machine wash if the care label permits.

Use a gentle cycle with mild detergent.

After cleaning, air-dry the backpack away from direct heat or sunlight to prevent shrinking and fading.

B. Storage Tips to Preserve Shape and Fabric Integrity

To maintain the shape and integrity of an Oxford fabric backpack, store it in a cool, dry place. Avoid hanging the backpack by its straps as this can distort the shape and place undue stress on the seams and fabric.

Proper Storage

Stuff the backpack with paper or fabric to maintain its shape.

Place it in a breathable dust bag to protect from dirt and moisture.

Preventing Fabric Damage

Keep the backpack away from sharp objects.

Do not place heavy items on top that may crush the fabric.

X. Conclusion

After exploring the historical origins of Oxford cloth, its unique weave, and its many advantages as a backpack fabric, it’s clear that Oxford cloth is not only strong and durable enough to withstand the wear and tear of everyday use, but its water-resistant properties are a powerful shield that protects its contents from accidental spills. At the same time, the low-maintenance nature of Oxford cloth means that it’s easy to clean and maintain, and won’t lose its elegance in even the busiest of life’s rhythms.

Whether you’re looking for a reliable traveling companion or want your everyday gear to be both functional and stylish, products made with Oxford cloth will be ideal for you. Interested in customized Oxford cloth backpacks? Contact us now!

0 Comments